Exploring essential monitoring technologies

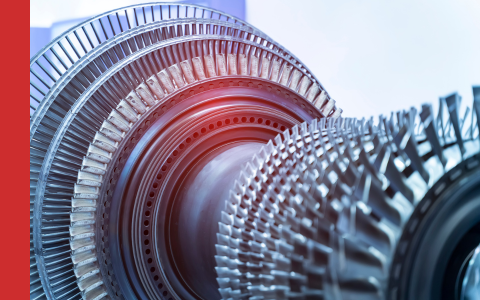

Welcome to our comprehensive guide on monitoring technologies. In this section, we delve into the fundamental aspects of condition monitoring, vibration monitoring and analysis, and torsional vibration. These technologies play pivotal roles in ensuring the reliability, efficiency, and safety of mechanical systems across various industries.

Discover proactive maintenance solutions and real-world applications through case studies and training opportunities.

Condition monitoring involves the continuous assessment of machinery health through parameters like vibration, temperature, and oil analysis. It enables proactive maintenance strategies, minimising downtime and maximising asset lifespan.

Vibration analysis monitors the vibrational characteristics of machinery to detect anomalies that could indicate faults or impending failures. It utilises advanced sensors and analytical techniques to ensure optimal performance and reliability.

Torsional vibration refers to angular oscillations in rotating machinery, particularly critical in engines and power transmission systems. Understanding and mitigating torsional vibration is essential for maintaining operational integrity and performance.

Explore real-world applications and success stories showcasing how Beran's condition monitoring solutions have made a significant impact across various industries. From improved operational efficiency to cost savings and enhanced reliability, our case studies illustrate the practical benefits of implementing our technology.

Dive into detailed analyses of specific projects and learn how our solutions have solved critical challenges for our clients.

Expand your knowledge with our glossary of essential terms and concepts related to condition monitoring and vibration analysis. Whether you're new to the field or looking to deepen your understanding, our comprehensive glossary provides clear explanations and definitions of key terms used in the industry.

Enhance your ability to interpret vibration analysis reports and understand the nuances of machinery health diagnostics with our curated collection of definitions.

Our Introduction to Rotating Machinery Vibration Diagnostics course is one of our most popular offerings, designed to help you enhance your skills and improve machinery performance. With small group sizes, participants benefit from personalised support and focused attention throughout the three-day program. Places are strictly limited, so book now to avoid missing out!

Duration: 3 days

Dates: Spring 2025

Location: Torrington, Devon, UK

Take the next step in mastering vibration diagnostics.