Helitune, XMOS, University of Bristol and the Queen Mary University of London have completed the IVHM-EVOLVE project.

The IVHM-EVOLVE project, co-funded by Innovate UK, was a 3½ year collaboration between Helitune, XMOS, University of Bristol (UoB), and Queen Mary University of London (QMUL), to develop new Integrated Vehicle Health Monitoring (IVHM) technologies to support UK business within the aerospace industry.

The project focused on the advancement of health monitoring systems, combining Autonomous Distributed Sensor innovation with Nanogenerator Science.

The original aims of the project were:

- to develop an ecosystem of intelligent self-organising sensor nodes that adapt and prioritise their resources around the current health of the aircraft

- to develop tiny, but powerful, Digital Signal Processing (DSP) sensor nodes through the application of an innovative multi-core microprocessor system-on-chip technology

- to develop autonomous, wireless sensors, combined with novel energy harvesting devices, that can be embedded in hard-to-reach places (e.g. above the rotor head).

- To develop prognostic algorithms to enable Real-Time Big Data Analytics.

- The combined technologies would provide a small, low-cost, low installation impact, flexible and effective IVHM solution, reducing barriers to entry and substantiating the business case for health monitoring on helicopters of all sizes, especially smaller aircraft where it has not been previously possible to fit IVHM systems.

Current IVHM Systems

A typical RTB system installation currently consists of one control/data storage unit (purple), four accelerometers (red) 2 tachos (yellow), and one blade tracking camera (green). Each sensor is connected to the control/data storage unit by a cable for data and power supply. The control unit can typically collect and process data from multiple rotors and test components at the same time. An IVHM system may consist of up to 16 accelerometers for a small aircraft and 40 to 60 for a large aircraft.

IVHM-EVOLVE

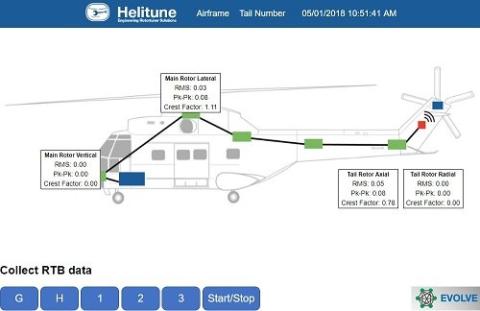

The IVHM-EVOLVE concept was for single-channel sensor nodes to be installed near the components being monitored. The nodes will be connected in series, requiring only one cable for data and power distribution, significantly reducing the weight and installation impact of the system. Initially, the IVHM-EVOLVE system would utilise conventional accelerometers, connected to the sensor nodes via a short cable. Future systems will aim to incorporate a MEMS sensor into the node to further reduce the weight of the system. The image below shows a proposed IVHM-EVOLVE RTB installation with four accelerometers.

The IVHM-EVOLVE system consists of a network of intelligent sensor nodes, combining data acquisition and mass storage with the power to run real-time anomaly detection algorithms, and the ability to adapt and target resources to the health of the monitored components. Each of the sensor nodes is self-contained and performs all of the processing for one measurement channel. The data is then broadcast on the network and received by the control unit or any other node that needs to receive a particular message. All data is synchronised to a master clock.

The IVHM-EVOLVE sensor nodes monitor the signals they are measuring for any changes that may indicate a potential component fault. When an anomaly is detected, the node sends an alert message and the system increases the frequency of data logging and can be configured to record additional condition indicators for the duration of the alert. This method of operation optimises the data collected during a flight, ensuring that the maximum amount of information is recorded during an anomalous event to help diagnosis. The IVHM-EVOLVE system is also robust to hardware failures, autonomously reconfiguring the remaining nodes to compensate for performance degradation.

Embedding the new IVHM-EVOLVE technology within existing and future helicopter models will maximise IVHM benefits, in order to provide safety enhancements, reduce operating costs, and improve the availability of helicopters. There is also a significant opportunity in the future to exploit the IVHM-EVOLVE technology for fixed-wing, UAVs, land and sea vehicles, as well as Industrial Plant and the Renewables Industry.

The IVHM-EVOLVE nodes communicate using Ethernet, which provides the speed and bandwidth required and enables power to be provided to the nodes using the unused connections in the Ethernet cables (Power over Ethernet (POE)). Time-Sensitive Networking (TSN), an audio/video standard, is used to provide precise time-synchronisation with low latency for messages broadcast on the network.

As part of the project, a GUI has been developed to display live data from the IVHM-EVOLVE Nodes and to enable an operator to interact with the system. The GUI, shown below, shows the current condition indicator values measured by each IVHM-EVOLVE node and indicates the alert status of each.

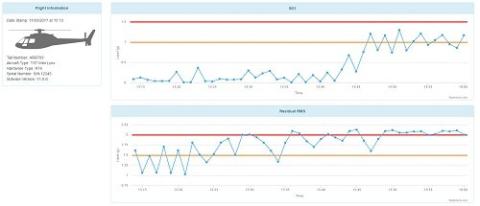

At the end of the flight, the HUMS data relating to the flight is collated into a data file which can then be uploaded to a ground station for display and further analysis.

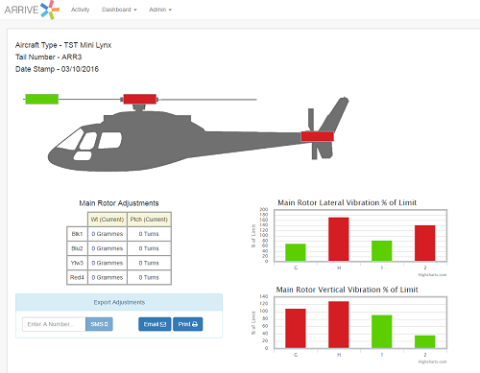

As part of a separate project, Helitune, in collaboration with Critical Software Technologies Ltd. (CSWT) and the University of Bristol has developed a cloud-based ground station for monitoring the health of assets (helicopters) and fleets – IVHM-ARRIVE. At the end of each flight, the relevant HUMS data can be sent to the IVHM-ARRIVE ground station for display and further analysis. When the IVHM-EVOLVE system is installed on an aircraft, it is anticipated that data will be downloaded at the end of each flight via Wi-Fi or removable data storage and then uploaded to IVHM-ARRIVE via the Internet.

Project conclusions

A Technology Demonstrator of the IVHM-EVOLVE sensor system has been developed. The system consists of a self-organising network of single-channel acquisition nodes providing distributed processing and synchronous multi-channel data acquisition. The system is able to adapt to the current health of the monitored system by changing the way data is measured and processed in reaction to an event detected by one or more nodes.

Any number of sensors can be connected together to make a flexible and scalable system. The sensor nodes can be configured to accept inputs from many sensor types such as accelerometers and tachometers and input from other systems, such as blade tracking cameras, that use an RS485 interface. The nodes can be programmed to process the measured data to calculate condition indicators and FFTs that can be synchronised with a tacho pulse if required.

The nodes are small and lightweight. Communications and power are provided by a single cable and sensors are connected together in series, rather than having a separate cable from the system controller to each sensor. This reduces the weight and cost of the system and simplifies installation. This system is at TRL 5.

Autonomous wireless sensors have been developed that are small and lightweight and can be installed in hard-to-reach places. The wireless sensors contain a tri-axis MEMS accelerometer and a temperature sensor. The electronic components have been carefully selected for low power requirements and the processor and wireless transmitter have been optimised for minimum power usage. The wireless sensors can be powered by an internal battery or an external nanogenerator. The wireless sensor is now at TRL 5.

Piezoelectric energy harvesting devices (nanogenerators) have been developed to harvest the energy from the environment (e.g. helicopter gearbox) to provide power for the wireless sensor. The design of the nanogenerators has been optimised to maximise the output voltage and power and the fabrication procedure has been improved and standardised. The nanogenerators are at TRL 3.

Prognostic algorithms have been developed to enable real-time analysis of data recorded by the IVHM-EVOLVE sensor system. The algorithms have been developed to adapt in response to the highly flexible deployment of the sensor array and optimised for Automated Regime Detection and anomaly detection using a small set of data recorded using existing Helitune equipment. Specifically, a new implementation of the Extreme Value Theorem (EVT) has been developed which accommodates load dependency i.e. the operating condition of the machine. Further testing and optimisation of the algorithms will be required once representative data has been collected from an installed IVHM-EVOLVE sensor system. The resulting diagnostics will permit enhanced decision-making, enabling meaningful and timely maintenance. The prognostic algorithms are at TRL 4.

Future development

Further work, in collaboration with an OEM, is required to develop a prototype IVHM system at TRL 7 that can be deployed in two different airframes in preparation for Aircraft Type Certification. The system will combine wired and wireless sensors in a robust system-level configuration.

Key areas of development

- Miniaturisation of electronics and packaging for installation in extreme and highly regulated environments

- Reconfigurable sensors to match component level operating behaviour

- Optimise wiring - combined power and data to reduce weight and installation impact

- System-level robustness through network-level re-configuration and sensor clustering

- Local intelligence and decision support

- “Edge AI” (artificial intelligence in the device)