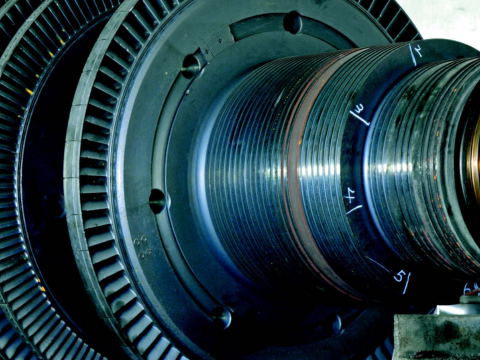

Parallel data acquisition for up to 64 vibration sensors, recommended for gas and steam turbines.

- Modular construction

- 19” rack mounting

- Up to 64 dynamic vibration channels

- Acceleration, velocity, and displacement inputs

- Up to 4 x 1/rev phase marker inputs

- Links to Site Digital Data Systems

Protection and condition monitoring systems are essential to monitor critical assets and understand machinery health for long-term safe, efficient operation by plant owners and operators to prevent machine failure, and planning maintenance tasks and activities.

Automated vibration trip system providing API670-compliant (American Petroleum Institute) machinery protection with integrated condition monitoring functionality.

Detecting and addressing harmful torsional vibrations in shaft lines

TORSO’s automatic detection and protection functionality eliminates your worries about excessive torsional vibrations in today’s situation of constantly changing grid circumstances.

TORSO Detect simply plugs into your existing system and monitors the torsional vibrations using the available array of sensors. It is an affordable early-warning system that enables you to take measures if needed.

Detecting and addressing harmful torsional vibrations in shaft lines.

TORSO’s automatic detection and protection functionality eliminates your worries about excessive torsional vibrations in today’s situation of constantly changing grid circumstances.

TORSO Detect simply plugs into your existing system and monitors the torsional vibrations using the available array of sensors. It is an affordable early-warning system that enables you to take measures if needed.

The PlantProtech PROTOR Mobile™ is a high-speed data acquisition and powerful diagnostic system for critical rotating machinery.

Key features

- Up to 32 parallel dynamic and static channels, 4-speed signals

- 24-bit ADC resolution

- Wifi and LAN connectivity

- Remote 4G access

- Link to plant historians, such as OSI Pi

- Lightweight - less than 7kg

Revolutionise your calibration and transducer manufacturing procedures and processes with the complete control provided by the Beran TransCal™ range, which includes remote configuration, transducer calibration, and traceable storage of every calibration in an easy-to-use PC-based environment.

The Beran TransCal™ Workstation enables ‘turnkey’ calibration of vibration transducers with charge, voltage, current or current excitation interfaces, along with electrostatic microphones, without the need for laborious and time-consuming manual calibration. Simply mount the transducer, select the required test profiles, and click ‘run’ to perform calibration in accordance with ISO 16063-21

The PlantProtech™ Auto Archive Downloader provides automatic file retrieval from remote sites to a central location (e.g. Technology Centre) for rapid review.

The application has the additional dual functionality of data archiving, either to local IT infrastructure or to a central Technology Centre, etc.

Receive periodic updates from Beran PlantProtech™ Analysers via the automated Email Vibration Alert interface straight to your PC inbox or mobile phone. Stay in touch 24/7, wherever you are, and remain informed about any changes in the vibration status or condition of your machine, assisting in the prevention of potential issues before they occur.

The TransCal™ Data Export Application allows the fully customised export of all test data in a text format according to a user-specified file type (e.g. .csv, .dat), allowing semi-automatic integration of the results held within the Beran TransCal Database to external user-specific database systems.

Central PC data store for all your PlantProtech™ Analyser historic data.

View your plant's health at a glance, with a customisable mimic.

- Ideal for plant operators

- Fleet-wide overview

- Traffic light display

- PlantProtech™ Vision quick launch