The challenges of high-temperature vibration measurement

For over 40 years, DJB Instruments has engineered accelerometers for increasingly demanding conditions. As industries push temperature boundaries—from 400°C exhaust systems to 900°C turbochargers—sensor performance must remain accurate, stable, and safe. This article explores the technologies, materials, and innovations that enable reliable vibration monitoring in extreme environments.

Operating in environments up to 900°C

Typical applications often require operation at 400°C, but in extreme cases such as exhaust and turbocharger testing, the temperature can reach as high as 900°C. These conditions are exceptionally harsh for any sensor, especially those designed to deliver dynamic response across temperature ranges that significantly alter material dimensions and behaviour.

To meet these challenges, DJB employs several key design features:

- Mechanical coupling of the mass and piezoelectric element, removing the need for adhesives

- Use of high-performance metals such as Inconel for accelerometer bodies

- Integral stainless steel or Inconel-sheathed cables

- Glass-to-metal sealed connectors

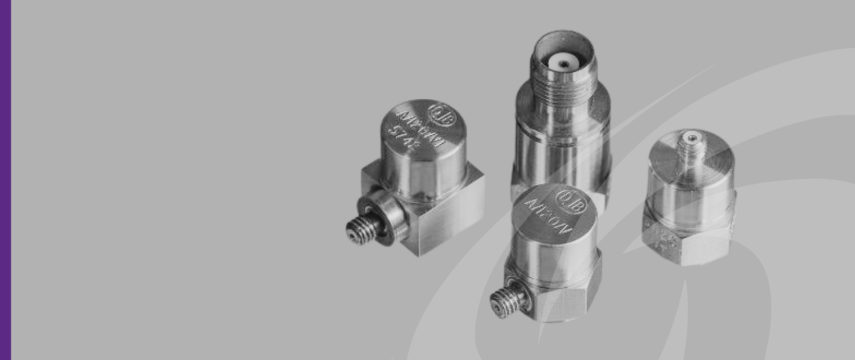

Current solutions: materials and measurement range

Using advanced ceramics and robust mechanical designs, DJB’s charge output accelerometers can operate at 450°C and above. These high-temperature solutions are already deployed in demanding industrial and aerospace applications for machine, system, and engine health monitoring.

IEPE advances: pushing from 125°C to 185°C

IEPE (Integrated Electronics Piezoelectric) technology has progressed significantly. While the standard upper limit used to be 125°C, most DJB monoaxial and triaxial accelerometers can now operate reliably up to 185°C. Achieving this required the development of enhanced electronics capable of maintaining stable bias voltage and dynamic range under elevated conditions.

Unique cooling solution for turbocharger testing

In extremely high-temperature environments, such as turbocharger surface testing, DJB’s water-cooled accelerometer design is an industry standard. This solution enables a triaxial accelerometer to be mounted directly onto surfaces up to 900°C. A simple and affordable windscreen washer pump provides constant water flow, maintaining safe internal temperatures for the sensing elements. This innovation also makes IEPE variants viable in these applications. First introduced in the 1990s, this cooling approach has continued to evolve and expand its capabilities.

Looking ahead: the future of high-temperature sensing

The next generation of piezoelectric accelerometers is already in development. Future models aim to:

- Integrate wireless communication

- Incorporate newly developed piezoelectric materials

- Extend temperature range capabilities to 600°C and beyond

Emerging requirements include not only high-temperature vibration measurement, but also dynamic explosive pressure detection. These trends are driving DJB deeper into the field of materials science to ensure continued innovation and relevance.

Have a high-temperature challenge? Talk to us.

If you're working on a high-temperature application or preparing for a project with extreme environmental demands, we’re here to help. Our team can offer tailored advice, recommend proven solutions, or discuss custom sensor development based on your requirements.

Use our online contact form to share your needs, and we’ll get back to you promptly. Prefer to speak to someone? You can also reach our sales team directly.

Contact our experts or call us on +44 (0)1638 71 22 22

Dive into DJB’s growing library of expert-written resources, including technical articles, selection guides, and in-depth explainers on accelerometers, cables, and signal conditioning.

Whether you’re specifying new sensors or troubleshooting complex setups, our content is designed to support your success.