Understanding torsional vibration: A guide for engineers

Introduction

What is torsional vibration?

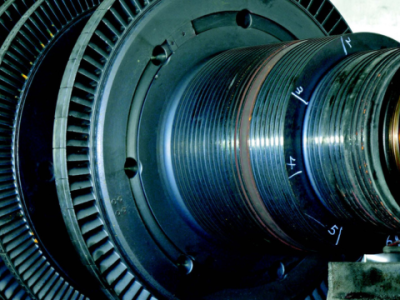

Torsional vibration refers to the oscillatory motion of rotating objects, particularly in machinery and power transmission systems, where the rotational forces create twisting and bending along the shafts. This phenomenon can lead to mechanical stress, premature wear of components, and even catastrophic failures if not properly managed.

Key characteristics

- Causes: Originates from irregularities in the torque transmission system, such as combustion engines, turbines, or electric motors.

- Effects: Impacts operational stability, efficiency, and longevity of machinery.

Benefits of safeguarding against torsional vibration

- Enhanced reliability: Mitigating torsional vibration minimises wear and tear on machinery components, thereby enhancing overall reliability and uptime.

- Improved safety: Reduces the risk of sudden failures that could endanger personnel and assets.

- Cost savings: Prevents unplanned downtime and costly repairs, optimising operational efficiency.

- Enhanced performance: Ensures consistent performance of machinery under varying operational conditions.

- Regulatory compliance: Meets industry standards and regulatory requirements for equipment safety and reliability.

How torsional vibration analysis helps

- Detection: Early identification of vibration patterns that indicate potential issues.

- Preventive maintenance: Allows for proactive maintenance scheduling to address developing problems before they escalate.

By understanding and effectively managing torsional vibration, industries can safeguard their investments in machinery and ensure long-term operational success.

In summary

Understanding and managing torsional vibration is critical for the optimal performance and longevity of machinery. Torsional vibration, caused by irregularities in torque transmission systems, can lead to significant mechanical stress and potential failures if left unchecked. By implementing effective torsional vibration analysis, industries can enhance reliability, improve safety, reduce costs, and ensure consistent performance.

Proactive detection and preventive maintenance are key to mitigating the adverse effects of torsional vibration, thereby safeguarding investments and adhering to regulatory standards. Ultimately, mastering torsional vibration control is essential for maintaining the efficiency and safety of power transmission systems and rotating machinery.

Talk to us about your condition monitoring requirements

Our condition monitoring specialists are on hand to ensure you get the right product for your needs.

Among the potentially harmful conditions for turbo groups, torsional vibration is generally overlooked although it can lead to dramatic failures. TORSO ENGIE Laborelec provides detection and protection solutions that address this issue effectively.