Machinery Health State Detection (mSTATE) supporting future net zero energy generation

Innovate UK Project: Noise removal in gas circulator vibration signals | Beran, Bristol University and EDF Energy

Beran, in collaboration with Bristol University and EDF Energy, completed an Innovate UK grant-funded project to improve noise removal on gas circulator frame vibration signals. The project focused on removing 50Hz noise from power drive signals, enhancing the accuracy of condition monitoring for induction slip motors in high electrical noise environments.

This partnership led to the development of innovative solutions that significantly improve the reliability and safety of critical infrastructure. The study highlights the importance of integrating advanced technology for the reliability and safety of industrial operations.

Abstract

Machinery Health State Detection (mSTATE) supporting future net zero energy generation

Next-generation Machinery Health State Detection (mSTATE) product - combining state-of-the-art digital signal processing hardware and novel mathematical algorithms for future net zero energy generation.

This 18-month collaborative project will result in a step-change in the value of existing machinery protection systems through the development of innovative and adaptive machinery failure state detection processing and algorithmic technologies, to improve machine safety and reliability through earlier fault detection and avoidance of false alarms.

The resulting diagnostics will permit enhanced decision-making, enabling meaningful and timely maintenance actions within industrial market sectors. The technology will be applicable for monitoring of all critical rotating machines where failure may impair safety, incur significant costs, adversely affect the electricity supply or violate environmental standards.

The consortium, led by Beran Instruments Ltd. (a UK-based SME), includes EDF Energy Nuclear Generation Ltd. and the University of Bristol (UoB).

Visit the UK Research and Innovation website

Project highlights

- Research and Development: The project, named Machinery Health State Detection (mSTATE), aimed to develop a new capability to subtract electrical noise from sensor signals, with funding from Innovate UK.

- Collaborative partnership: Collaboration between Beran, Bristol University, and EDF Energy Torness Nuclear Power Station enabled real-world testing and validation of the developed solutions.

- Technology integration: The project delivered a novel algorithm capable of subtracting 50 Hz mains frequencies from sensor signals, allowing the visualisation of true vibration signals without expensive analogue signal conditioning systems.

The success of the algorithm

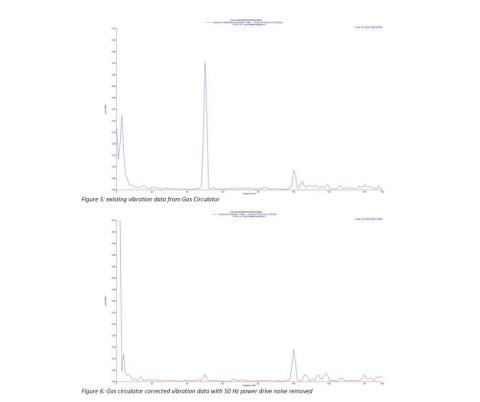

Figures 5 and 6 illustrate the effectiveness of the developed algorithm in eliminating the 50 Hz noise, analogous to the functionality of noise-cancelling headphones. The algorithm successfully removes the prominent spike caused by electrical noise, allowing for clearer visualisation of the true vibration signals.

Technical insights

- Research focus: The project addressed challenges in monitoring induction slip motors in high electrical noise environments, necessitating the use of charge sensors and specialized signal conditioning amplifiers to visualise true vibration signals.

- Operational context: The study focused on Torness Nuclear Power Station gas circulators, emphasising the importance of condition monitoring in critical infrastructure.

- Algorithm development: Various techniques were explored to subtract 50 Hz noise from vibration signals, improving signal clarity and enabling accurate machine health monitoring.

- Practical implementation: The developed algorithms were embedded into Beran's PlantProtech Condition Monitoring System (PCMS), demonstrating successful noise removal from vibration data acquired from installed sensors.

Conclusion

In conclusion, the mSTATE project successfully deployed a practical tool to eliminate problematic slip frequencies, aiding in analysing closely aligned frequencies in electrical machines. Demonstrated on gas circulator data from Torness Power Station, the project introduced a novel algorithm enabling the complete subtraction of 50 Hz mains frequencies from sensor signals, allowing end users to visualize true vibration signals for the first time. This advancement, achieved with minimal computational costs, enables the trending of machine health over time without specialised analogue signal conditioning systems.

The project acknowledges the crucial support of Innovate UK funding, along with the invaluable assistance from EDF Energy and engineers at Torness Nuclear Power Station.

Biographies

- Xintian Chi: Completed his undergraduate degree and PhD at the University of Bristol in Mechanical Engineering and Structural Health Monitoring. He acted as the principal researcher on the mSTATE project.

- Nick Lieven: A professor of Aircraft Dynamics at the University of Bristol with 30 years of experience in Structural Health Monitoring and over 150 published papers. View profile on Bristol University website

- Duncan Affleck: Beran Global Sales and Business Development Manager, has been working in the condition monitoring world for almost three decades supplying machinery vibration diagnostic systems worldwide.

Keywords

Keywords: vibration monitoring, condition monitoring, induction motors, electrical noise, rotating machinery, machine diagnostics, data analysis

Resources

- Visit the EDF Energy Torness Power Station website

- bristol.ac.uk - Condition Monitoring of Induction Slip Motors in High 50 Hz ...

- gtr.ukri.org: Projects (3657)

Downloads

Download the full academic paper below.